-

Products

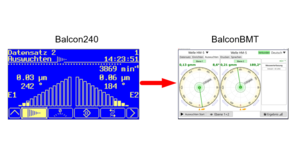

- Balancing systems

- Operating modules

- Balancers

- Power and data transmission

- Sensors for balancing technology

- AE acoustic emission systems

- Cable

- Connection boxes

- Balancing machines

- Clamping equipment

-

Balancing rings

- Balancing rings with fixed-location equalization

- Splited balancing rings with fixed-location equalization

- Balancing rings with axial segments and internal threads

- Balancing rings with axial segments and mounting holes

- Balancing rings with radial segments

- Pair of balancing rings with cross knurls

- Balancing ring pair with cross knurl and collar ring

- Balancing ring pair with cross knurl and carrier ring for shrinking

- Balancing ring pair with cross knurl and carrier ring for clamping

- Pair of balancing rings with 360° scaling

- Scale rings

- Accessories

- Rapid grinding units

- Training unit for apprentices

- Aluminium profile technology

- Conveyor technology

- Applications

- Contract balancing

- Company

- Contact

![[Translate to english:] [Translate to english:]](/fileadmin/_processed_/4/a/csm_OP20_ca46cdde1f.png)

![[Translate to english:] [Translate to english:]](/fileadmin/_processed_/8/8/csm_OP40_29046b2bf4.png)

![[Translate to english:] [Translate to english:]](/fileadmin/_processed_/d/4/csm_OP100_5decfd39c0.png)